Environmental and Economical

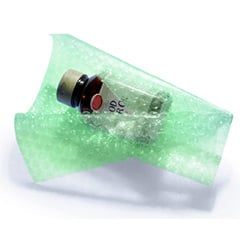

It can be difficult to find packaging products that have a low environmental impact that are also at an economical cost and highly effective. Emerald bubble packaging is one of the most innovative protective packaging products offered by IPG which allows you to protect your products sustainably without sacrificing quality or cost.

Bubble Packaging

Emerald bubble packaging has specific features that set it apart from other bubble packaging products. Made from 100% Polyethylene and is #4 recyclable. As an LDPE (low density polyethylene) product containing no nylon, it can be recycled with Store Drop-Off recycling programs. Each roll depicts a How2Recycle label. Other bubble packaging products contain nylon and are #7 recyclable which are not easily recyclable and are full of multi plastics. Emerald bubble contains 25% PCR (Post Consumer Resin), which supports a sustainable manufacturing process, lessening the environmental impact both in the product and in the manufacturing process.

Going Green

Emerald bubble packaging gets its name from its emerald, green color, which coincides with its low environmental impact- when you use it, you are literally “going green”. The color makes easily recognizable and translucent, allowing the product it protects to still be visible. The Emerald bubble features a slightly tacky film surface which helps when sliding or shifting during packing and shipping is a concern. Emerald also has excellent air retention that guarantees reliable protection through short cycle shipments.

Enjoy Versatility

Use Emerald bubble packaging to secure many products. For example, ceramics, gifts, electronics, medical and dental products or tools, and pharmaceuticals. It is food contact safe, making it perfect for food products. It is available from IPG in three standard roll stock sizes (½”, 5/16”, and 3/16” as well as pouches (lip and tape or flush). IPG has manufacturing plants in several major markets, such as Toronto, New York City, Atlanta, Chicago, Dallas, and Los Angeles so orders can be fulfilled quickly with lower freight costs.