A Guide to Efficient Product Stacking with Tishma Technologies

In the dynamic world of packaging automation, the art and science of palletizing play a pivotal role in the efficiency of a product’s journey from the manufacturer to the market. Palletizing, the process of stacking products on a pallet for transport and storage, is a critical last step in all packaging lines, especially for industries such as food and beverage, pharmaceuticals and nutraceuticals, and consumer packaged goods. This guide delves into the fundamentals of palletizing, highlighting key techniques for optimizing product placement and stability, ensuring your products reach their destination in pristine condition.

Pallets efficiently handle boxes and cartons, bags of materials like grain or chemicals, and drums or barrels for liquids. Construction materials such as lumber and bricks, bulky items like furniture and appliances, and automotive parts are also commonly stacked on pallets.

Understanding Palletizing

Palletizing is more than just stacking product. It’s a strategic process of arranging products on a pallet in a way that maximizes space, ensures stability, and protects the items during transit. Efficient palletizing reduces the risk of damage, optimizes storage space, and enhances the overall logistics efficiency.

Type of Palletizing

- Manual Palletizing: This traditional method involves workers stacking products by hand. It’s flexible but can be time-consuming, physically demanding, and costly while also increasing the risk of personnel injury.

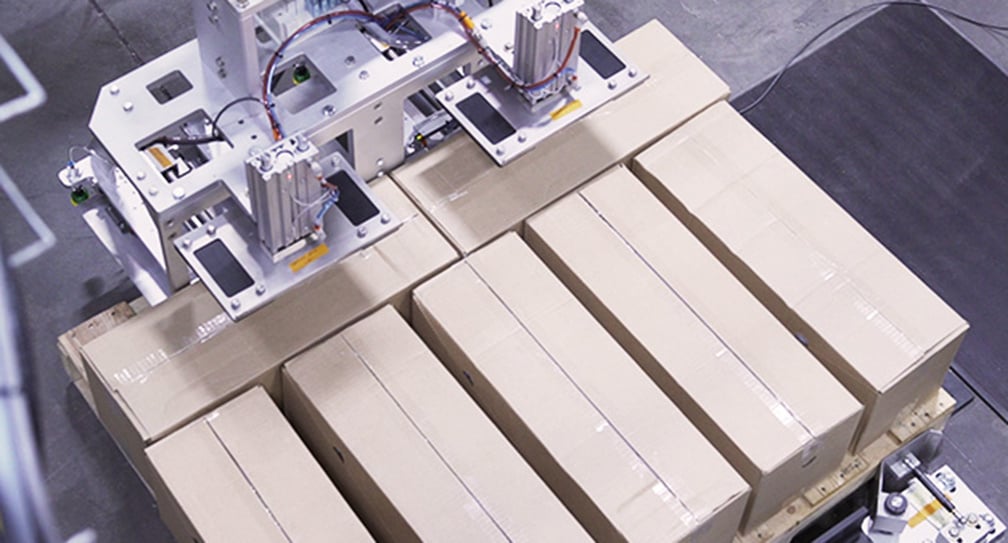

- Automated Palletizing: Utilizing advanced machinery like robotic palletizers is faster, more consistent, reduces injury risk and is a necessity for busy packing lines in high-volume operations.

Palletizing Patterns

- Column (or Block) Stacking: Products are stacked directly on top of each other, aligning corners and edges. This maximizes vertical strength but can be less stable horizontally.

- Interlocking (or Brick, Row, or Pinwheel) Pattern: Boxes are alternated at each layer, enhancing stability during handling and transit.

Optimizing Product Placement

The way products are placed on a pallet is crucial for stability and space utilization. Here are some best practices:

- Uniform Box Sizes: Using boxes of the same size helps in creating a more stable and uniform load.

- Proper Weight Distribution: Heavier items should be placed at the bottom, with lighter items on top to prevent crushing and imbalance.

- Utilize the Entire Pallet: Products should be arranged to cover the entire pallet surface, reducing the risk of overhanging boxes that could lead to damage.

Enhancing Stability

A stable pallet is essential for safe transportation and storage. Here’s how to enhance stability:

- Stretch Wrapping: This involves wrapping the loaded pallet with stretch film to hold items in place securely and can be done manually or automated with a stretch wrapping machine.

- Strapping: Using straps, bands, and tapes can further secure the load, especially for heavy or unstable items.

- Edge Protectors: Placing these on the corners of the stacked pallet can prevent damage and maintain load integrity.

- Tier, Slip, or Layer Sheets: These sheets are placed between layers of products, typically boxes and cartons, to stabilize and evenly distribute weight throughout the pallet. Tier sheets are particularly effective for maintaining the integrity of layered stacking patterns.

The Role of Palletizers in Efficiency

Investing in automated palletizing solutions, like those offered by Tishma Technologies, can significantly enhance the efficiency of your packaging line. These systems can:

- Increase Production Throughput: Automated palletizers handle products faster and more consistently than manual methods.

- Reduce Labor Costs and Injury Risks: Automating the palletizing process minimizes the physical strain on workers and associated costs.

- Improve Consistency and Quality: Machines provide uniform stacking, reducing the risk of product damage during transport.

- Maximize Shipping Loads: Robotic palletizers can stack pallets higher than manual workers can, optimizing space utilization in shipping loads and increasing trailer yield per shipment.

Mastering the essentials of palletizing is a crucial aspect of the packaging line, impacting the efficiency, safety, and cost-effectiveness of product distribution. Whether through manual techniques or advanced automated solutions, optimizing palletizing processes is key to maintaining product integrity and streamlining operations.

Palletizing Equipment from Tishma Technologies

Tishma Technologies’ innovative palletizing lineup features the OpenStack and Tetristack, each designed for specific industry needs. The OpenStack, a mobile guardless palletizer, offers exceptional flexibility and safety in a compact footprint, ideal for space constrained packing lines. The Tetristack, a modular palletizing system, is tailored for complex packing challenges, providing extensive customization options including multiple infeeds/outfeeds, pallet and slip sheet dispensers, and custom heavy-load robot end-of-arm-tooling design.

Contact us today to discover the palletizing solution for your unique challenges and take the first step towards optimizing your packaging process.