In the dynamic landscape of e-commerce, where B2B transactions surged significantly in 2021, effective packaging plays a pivotal role in ensuring customer satisfaction and minimizing logistical challenges. As businesses strive to meet evolving consumer demands, the choice between cardboard and corrugated cartons emerges as a crucial consideration for secure product shipment.

Distinguishing Characteristics: Cardboard vs. Corrugated Cartons

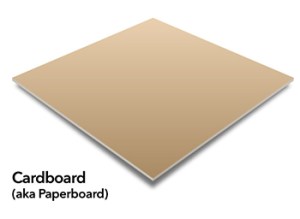

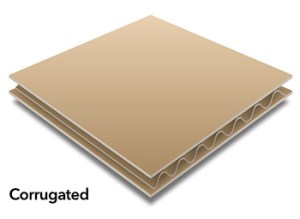

While colloquially used interchangeably, it’s essential to discern the disparity between these packaging materials. Cardboard generally, denotes a thick paper stock or heavy paper pulp, commonly employed in items like cereal boxes or greeting cards. In contrast, corrugated cartons comprise three layers of paper—an inner liner, outer liner, and fluted medium—offering enhanced durability and structural integrity, thereby mitigating concerns regarding product damage during transit.

Advantages of Corrugated Cartons

The advantages of corrugated cartons over cardboard extend beyond mere durability. These include superior product protection, cost efficiency, and environmental sustainability. Notably, corrugated materials boast a high strength-to-weight ratio, making them lightweight yet robust options for shipping. Moreover, their recyclability aligns with modern consumer preferences for eco-conscious packaging solutions.

Sealing Solutions: Water-Activated Tape (WAT)

An additional enhancement to the packaging process lies in the utilization of water-activated tape (WAT) for sealing corrugated cartons. Crafted primarily from Kraft Paper, WAT forms a permanent bond with the carton upon activation with water, rendering it tamper-evident and ideal for securing various-sized packages. Unlike conventional plastic packaging tape, WAT offers unparalleled strength and resilience, capable of withstanding diverse environmental conditions.

Customization and Branding Opportunities

Furthermore, the versatility of WAT extends to customization options, enabling businesses to imprint their logos directly onto the tape, thereby bolstering brand visibility. Whether opting for manual or electric , organizations can tailor their carton-sealing methods to suit their specific operational requirements.

Optimizing Packaging Processes

In essence, while cardboard remains suitable for certain applications such as cards and lightweight packaging, corrugated cartons emerge as the preferred choice for safeguarding products during transit. By leveraging the durability, cost efficiency, and eco-friendliness of corrugated materials, coupled with the security provided by water-activated tape (WAT), businesses can optimize their packaging processes and uphold customer satisfaction in an increasingly competitive market landscape.