Unleashing the Power of Natural Rubber Adhesive

Are you tired of tapes not sticking? Discover the solution with the power of natural rubber adhesive. This comprehensive guide explores the benefits, applications, and tips for using natural rubber adhesive effectively.

Understanding Natural Rubber Adhesive: What Makes It So Powerful

Natural rubber adhesive is a powerful adhesive that is known for its exceptional sticking power. It is made from natural rubber, which gives it a unique set of properties that make it ideal for various applications. The natural rubber used in the adhesive provides excellent tackiness, ensuring that it bonds strongly to different surfaces.

One of the key reasons why natural rubber adhesive is so powerful is its ability to conform to irregular surfaces. It can easily adhere to rough, uneven, or curved surfaces, providing a secure bond. This makes it a versatile choice for both smooth and textured materials.

Another factor that contributes to the power of natural rubber adhesive is its resistance to heat and moisture. It can withstand high temperatures and exposure to water, making it suitable for both indoor and outdoor use. Whether you need to secure items in a hot environment or in a wet environment, natural rubber adhesive will not let you down.

In addition to its sticking power, natural rubber adhesive also offers good flexibility. This means that it can withstand movements and vibrations without losing its bond. It is ideal for applications that require some degree of movement, such as packaging, sealing, and bonding of materials.

Overall, natural rubber adhesive is a powerful adhesive that combines exceptional sticking power, versatility, and resistance to heat and moisture. Its unique properties make it an excellent choice for a wide range of applications.

Applications of Natural Rubber Adhesive: Versatility at Its Best

Natural rubber adhesive is known for its versatility, making it suitable for a wide range of applications. Its exceptional sticking power and ability to conform to irregular surfaces make it an ideal choice for bonding materials in various industries.

One of the primary applications of natural rubber adhesive is in the packaging industry. It is commonly used for sealing boxes, securing labels, and bonding different types of packaging materials. Its strong adhesive properties ensure that the packaging remains intact during transportation and handling.

Another industry where natural rubber adhesive finds extensive use is the construction industry. It is used for bonding materials such as wood, metal, plastic, and glass. Whether it's for installing flooring, fixing tiles, or assembling furniture, natural rubber adhesive provides a reliable and long-lasting bond.

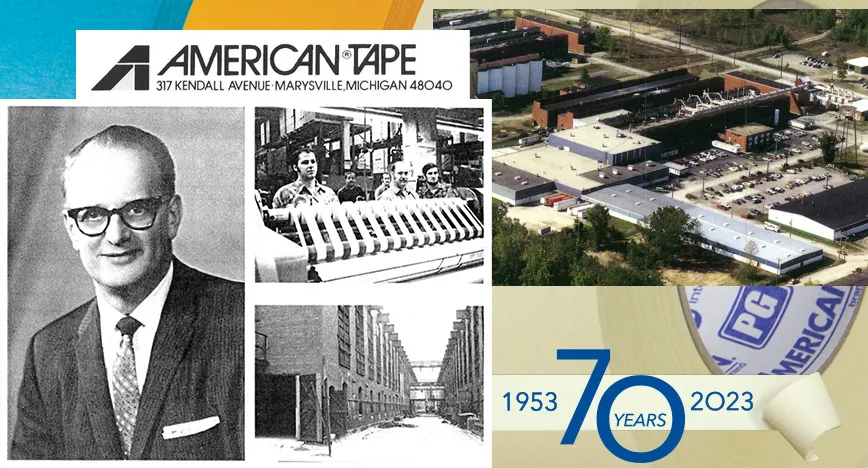

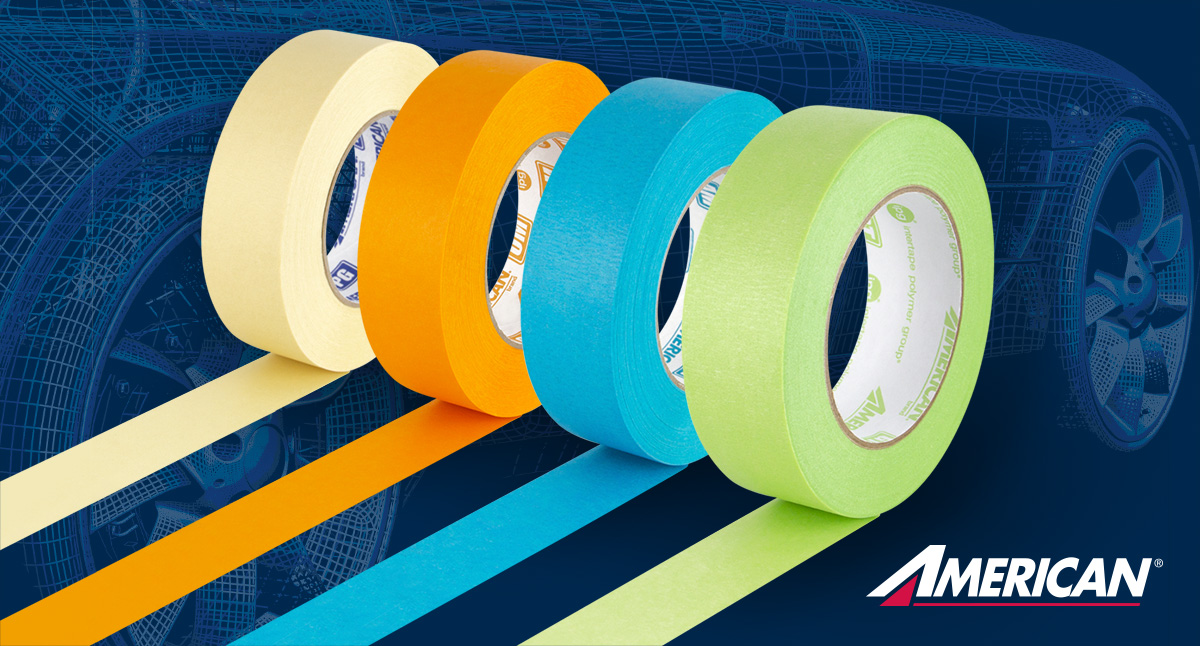

Natural rubber adhesive is also widely used in the automotive industry. It is used for bonding various components, such as trim, emblems, and weatherstripping. Its ability to withstand heat and moisture makes it suitable for both interior and exterior applications in vehicles.

Other applications of natural rubber adhesive include arts and crafts, electronics assembly, medical device manufacturing, and general-purpose bonding. Its versatility and reliability make it a go-to adhesive for many professionals across different industries.

Choosing the Right Natural Rubber Adhesive for Your Needs

When it comes to choosing the right natural rubber adhesive for your needs, there are a few factors to consider. These factors will help ensure that you select an adhesive that is suitable for your specific application.

Firstly, consider the surface you need to bond. Different surfaces may require different adhesive strengths. If you're bonding lightweight materials, a general-purpose natural rubber adhesive may suffice. However, if you're bonding heavy-duty materials or materials that are exposed to extreme conditions, you may need a stronger adhesive.

Secondly, consider the environmental conditions the adhesive will be exposed to. If the adhesive will be used outdoors or in environments with high temperatures or moisture, choose a natural rubber adhesive that has excellent resistance to these conditions. This will ensure that the adhesive maintains its bond and performance over time.

Lastly, consider the application method. Natural rubber adhesives are available in various forms, including tapes, liquids, and sprays. Choose a form that is convenient and easy to apply for your specific application.

By considering these factors, you can choose the right natural rubber adhesive that meets your specific needs and ensures a strong and long-lasting bond.

Tips and Tricks for Using Natural Rubber Adhesive Effectively

To ensure effective use of natural rubber adhesive, here are some tips and tricks to keep in mind:

1. Clean the surface: Before applying the adhesive, make sure the surface is clean and free from dirt, dust, oil, or any other contaminants. This will ensure a strong bond.

2. Apply the adhesive evenly: When applying the adhesive, ensure an even and consistent layer. This will help maximize the bonding strength.

3. Allow proper curing time: Natural rubber adhesive requires some time to fully cure and develop its maximum bond strength. Follow the manufacturer's instructions for the recommended curing time.

4. Apply pressure: After applying the adhesive, apply pressure to the bonded materials to ensure a strong bond. This can be done using clamps, weights, or by applying pressure with your hands.

5. Store properly: To maintain the adhesive's effectiveness, store it in a cool and dry place, away from direct sunlight and extreme temperatures.

By following these tips and tricks, you can ensure that you use natural rubber adhesive effectively and achieve the desired results in your applications.

Exploring Alternative Adhesive Options: Is Natural Rubber the Best Choice?

While natural rubber adhesive offers many benefits, it's always worth exploring alternative adhesive options to determine the best choice for your specific needs.

One alternative to natural rubber adhesive is acrylic adhesive. Acrylic adhesive offers excellent temperature resistance, UV resistance, and durability. It is commonly used in outdoor applications and for bonding materials that are exposed to high temperatures.

Another alternative is silicone adhesive. Silicone adhesive is known for its flexibility, high temperature resistance, and excellent electrical insulation properties. It is commonly used in electronics assembly, automotive applications, and medical device manufacturing.

Epoxy adhesive is another popular alternative. Epoxy adhesive offers exceptional strength, chemical resistance, and bond durability. It is commonly used in industrial applications, such as bonding metals, plastics, and composites.

Ultimately, the choice between natural rubber adhesive and alternative options depends on your specific needs and the requirements of your application. Consider factors such as temperature resistance, durability, flexibility, and bond strength to make an informed decision.

In conclusion, natural rubber adhesive is a powerful adhesive that offers exceptional sticking power, versatility, and resistance to heat and moisture. It is suitable for a wide range of applications and provides reliable and long-lasting bonds. However, it's always important to explore alternative adhesive options to ensure that you choose the best adhesive for your specific needs.

Post a comment